JIN XIANG has more than 30 years of experience in the design, manufacturing, and assembly of custom label printing machines, having produced thousands of bespoke printing machines for sticker labels, flexible packaging, self-adhesive labels, tickets, and more. Whether you are seeking a fully customized printing machine or following your own design, we are confident in our ability to offer optimal engineering solutions.

JIN XIANG is an expert in manufacturing flexo printing machines and have provided customers with machines capable of printing 1 to 13 colors. The printing materials, size, weight, plate cylinder diameter, main motor power and ink distributor power are all optional according to customer requirements, so please do not hesitate to reach out to us with your specific needs!

Any substrate that can be rolled up is capable of being printed on using our flexographic press machines. Applicable substrates include self-adhesive paper, laminated materials, BOPP film, shrink film, metallic material, petrochemical environmentally friendly materials and special materials.

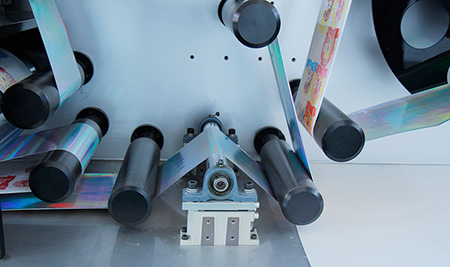

Rotary die cutting station with magnetic cylinder, rotary embossing cutting die

- Hardness: 45°

- Thickness: 0.95mm

- Depth: 0.69mm

-

Tension controller

Tension controllerThe tension controller automatically adjusts the tension based on the material thickness. This allows the printing machine to handle various printing substrates with a thickness ranging between 0.05mm and 0.5mm.

-

Servo system

Servo systemThe ink feeding system in each printing station is controlled by a servo motor and CNC computer, ensuring an accurate ink feeding and feeding speed adjustment during the printing process.

-

Corona treater

Corona treaterAn advanced corona treater efficiently removes dust and increases ink adhesion on the printing substrates, making these flexo printing machines applicable to printing on a variety of materials.

-

Web guide controller

Web guide controllerThe web guide controller is equipped with web guider sensors to correct material lateral deviation in forward motions, ensuring the printing accuracy.

The UV letterpress primarily uses an oil-based ink with a higher viscosity and stronger adhesion than dry ink, and thus, offers a clearer, bright, and more appealing printing effect.

The UV letterpress printing is the main printing station, with the printing dots and colors on the same printing plate. This ensures a single plate meets printing requirements for a thinner adhesive layer. Cold foil that goes through a UV printing station is also more applicable to stamping printing of small icons.

JIN XIANG’s flexo printing machines are used for printing on just about any substrate type to meet your needs. The market includes pressure sensitive label printing, self-adhesive label printing, flexible packaging printing, tube packaging printing (like toothpaste tubes and facial cleansers) and more.

JIN XIANG’s label presses are available in a flexible combination of units to meet diverse and strict printing requirements. The following units are customizable to meet your needs.

For example:- UV silk-screen printing

- Reverse printing

- Cold foil

- Static observation system

- Slitting and sheeting system

- Electrostatic eliminator

Different customers have different requirements for label presses, so with the exception of a standard configuration label press, a cold foil unit, slitting unit and other optional configurations are also available to meet the needs for multiple function applications. Please share the required plate cylinder type, number of printing stations, and optional configurations, and we will customize the right label press for your needs.

- Edge trimming unit (1 set)

- UV curing system(7 sets)

- Tension controller (1 set)

- Tools (1 sets)

- Printing plate mounter (1 sets)

- Flexo plate proofer (1 sets)

- Splicing table (1 sets)

- Printing unit (up to 13 color printing is available, depending on customer demands)

- Varnish unit (1 sets)

- Cleaning unit (1 set)

- Plate cylinder (optional size)

- Corona treatment unit (1 sets)

- Adhesive layer and reversing printing unit

- Rotary cross cutting unit

- Unwinder and rewinder (1 set respectively)

- Protective film laminator (1 sets)

Note:the unit varies from equipment to equipment for different configurations.

- Cold foil unit

- Gravure printing unit

- Round screen printing unit

- Slitting and sheeting system

- Static observation system

- Cooling system

- Electrostatic eliminator

- Lamination unit and cross over unit for multi layer label production

- Tel.:+86-13829126249

- E-mail:jhliwen@126.com